ERLEMANN+HUCKENBECK. MADE IN GERMANY FOR OVER 80 YEARS.

Erlemann+Huckenbeck manufactures technical moulded parts using thermosets and thermoplastics. We offer a portfolio of robust, durable operating elements. The majority of these are in stock and quickly available. We also produce customer orders. Our in-house toolmaking facility plus our high level of vertical integration at our site in Germany give us outstanding flexibility for creating customer-specific solutions and series-produced parts.

ERLEMANN+HUCKENBECK. MADE IN GERMANY FOR OVER 80 YEARS.

Erlemann+Huckenbeck manufactures technical moulded parts using thermosets and thermoplastics. We offer a portfolio of robust, durable operating elements. The majority of these are in stock and quickly available. We also produce customer orders. Our in-house toolmaking facility plus our high level of vertical integration at our site in Germany give us outstanding flexibility for creating customer-specific solutions and series-produced parts.

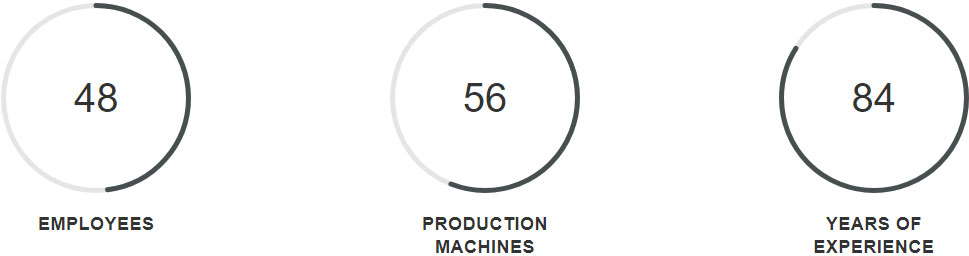

EMPLOYEES

PRODUCTION MACHINES

YEARS OF EXPERIENCE

COMPANY

Ernst Erlemann and Walter Huckenbeck founded our mid-sized company in 1936. Today, Erlemann + Huckenbeck is part of a family-run group of companies. In the German town of Radevormwald, 30 employees operate more than 50 plastics processing production machines.

CORE EXPERTISE

We are experts in high-quality plastic parts. Our core expertise concerns the production of technical moulded parts and grips – primarily made from thermosetting polymers. These elements are manufactured using the compression moulding method. Our production machines manufacture products weighing from less than one gram to large parts of 10 kg and beyond –

Made in Germany.

CORE EXPERTISE

We are experts in high-quality plastic parts. Our core expertise concerns the production of technical moulded parts and grips – primarily made from thermosetting polymers. These elements are manufactured using the compression moulding method. Our production machines manufacture products weighing from less than one gram to large parts of 10 kg and beyond –

Made in Germany.

MACHINERY

Thermoset processing using compression moulding involves semi and full automatic machines with a pressure capacity of 30 to 500 tons. Thermoplastic and thermoset injection moulding production uses machines with an injection force ranging from 250 kN to 2200 kN. We manufacture the compression and injection moulds

required ourselves at our site. For this, we have several CNC milling machines, EDM systems, grinders and lathes available in our mouldmaking department.

CUSTOMERS

We depend on reliability and longstanding partnership in every area. Products from Erlemann+Huckenbeck have been installed in a wide range of equipment for many decades. Our customers mainly operate in the following sectors:

– Machine construction

– Plant construction

– Electrotechnical industry

– Automotive

– Textile machinery

– Material handling

– Sports / leisure equipment

– Commercial enterprises

CUSTOMERS

We depend on reliability and longstanding partnership in every area. Products from Erlemann+Huckenbeck have been installed in a wide range of equipment for many decades. Our customers mainly operate in the following sectors:

– Machine construction

– Plant construction

– Electrotechnical industry

– Automotive

– Textile machinery

– Material handling

– Sports / leisure equipment

– Commercial enterprises

CERTIFICATION

High-quality materials, production in Germany and streamlined workflows – these are our key areas of focus. With this in mind, Erlemann+Huckenbeck is certified to ISO 9001:2015 by DNL GL.