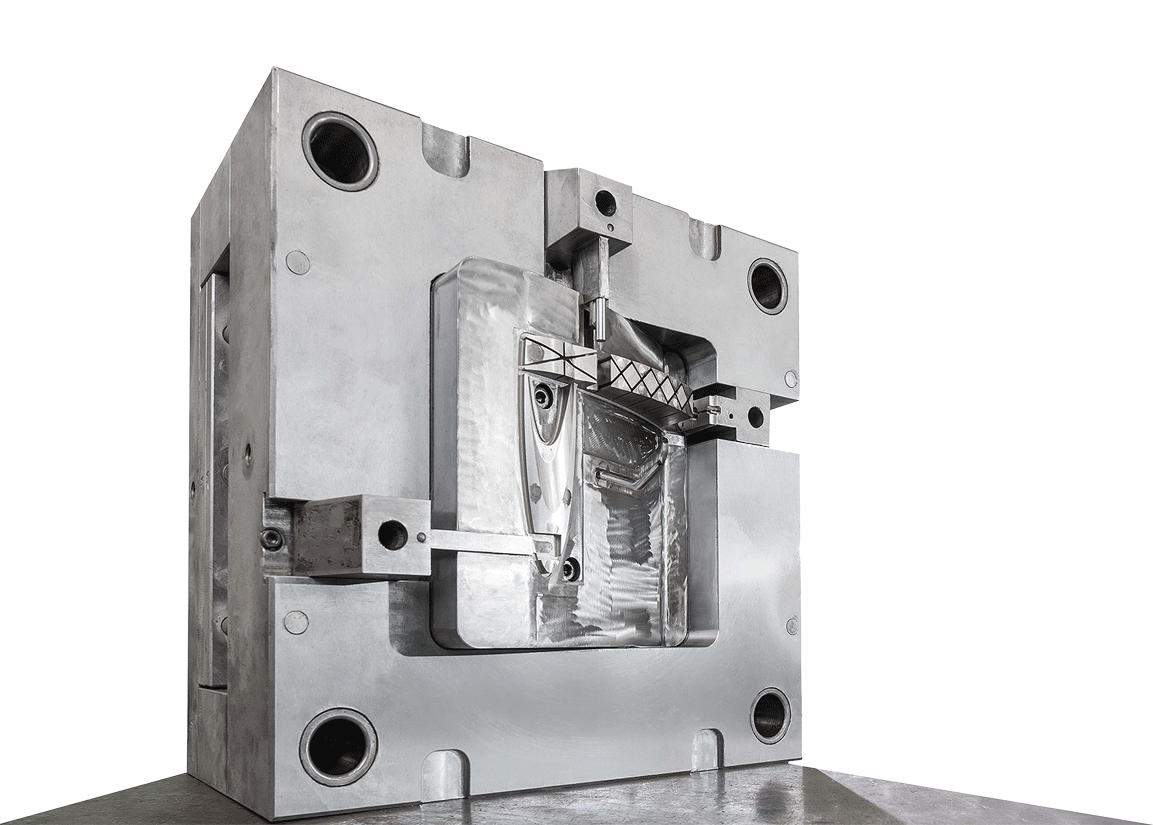

MOULDMAKING

Erlemann+Huckenbeck produces moulds to order. Delivered on schedule and tailored to thermoplastic and thermoset parts. High levels of quality and reproducibility are at the heart of what we do. From the CAD design to the finishing stage, we ensure the efficient production of compression and injection moulds for plastic parts.

PROJECT SOLUTIONS

Thanks to our high level of vertical integration, in-house mouldmaking facility and series production capabilities at our site in Germany, we are the ideal partner to create the plastic part you have in mind. We specialise in the compression and injection moulding of elements made from thermosetting and thermoplastic materials. Working together with you, our expert team will develop your product ready for series production in next to no time.

PROJECT SOLUTIONS

Thanks to our high level of vertical integration, in-house mouldmaking facility and series production capabilities at our site in Germany, we are the ideal partner to create the plastic part you have in mind. We specialise in the injection moulding of elements made from thermosetting and thermoplastic materials. Working together with you, our expert team will develop your product ready for series production in next to no time.

RAPID PROTOTYPING

Erlemann+Huckenbeck is there to support you right from the development phase of plastic products. We use 3D CAD technology to generate the necessary process data. We then convert this data into 3D models quickly and cost effectively. There are various methods to choose from here: stereolithography, laser sintering and vacuum casting technology.

We would be happy to help you!

Send us your enquiry and we will contact you as soon as possible with a proposal we are sure will be of interest to you!