PROJECT SOLUTIONS

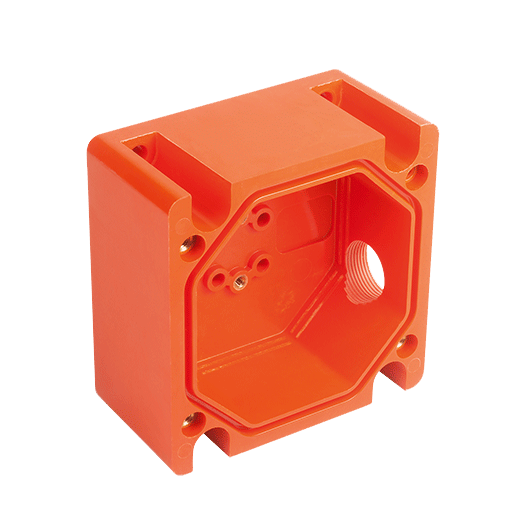

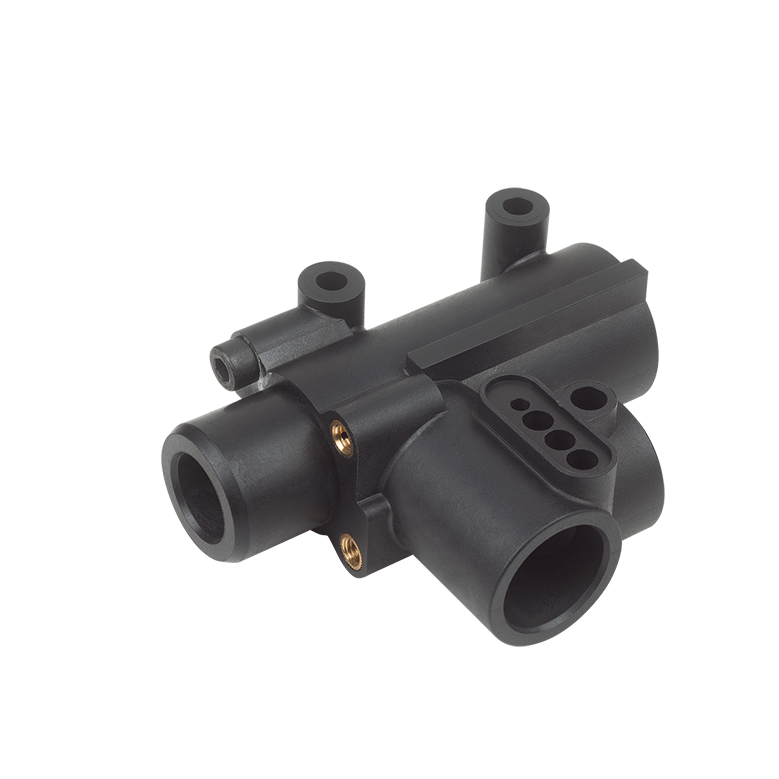

Erlemann+Huckenbeck is an expert in injection and compression moulding. We accompany your product from the idea all the way to its completion. Have you already designed the item in 3D? Or perhaps you only have a drawing or a sample? Then we can take care of the mould design, tool manufacture and series production. Professionalism you can rely on: over 80 years of experience in thermoset processing and 40 years working in thermoplastic processing speak for themselves!

Thermoset

We use 45 semi and full automatic machines to process the following moulding materials using compression and injection moulding techniques:

- Based on phenolic resin (PF)

- Based on melamine resin (MP, MF)

- Based on unsaturated polyester, saturated polyester (UP or SMC/BMC)

- Based on urea (UREA)

… to create technical parts of just a few grams to those with unit weights of 12 kg.

The pressure capacity of our machinery extends up to 500 tons for compression moulding or an injection force of up to 2200 kN for injection moulding.

Thermoset

We use 45 semi and full automatic machines to process the following moulding materials using compression and injection moulding techniques:

- Phenolic resin (PF)

- Melamine resin (MP, MF)

- Unsaturated polyester, saturated polyester (UP or SMC/BMC)

- Urea (UREA)

To create technical parts of just a few grams to those with unit weights of 12 kg.

The pressure capacity of our machinery extends up to 500 tons for compression moulding or an injection force of up to 2200 kN for injection moulding.

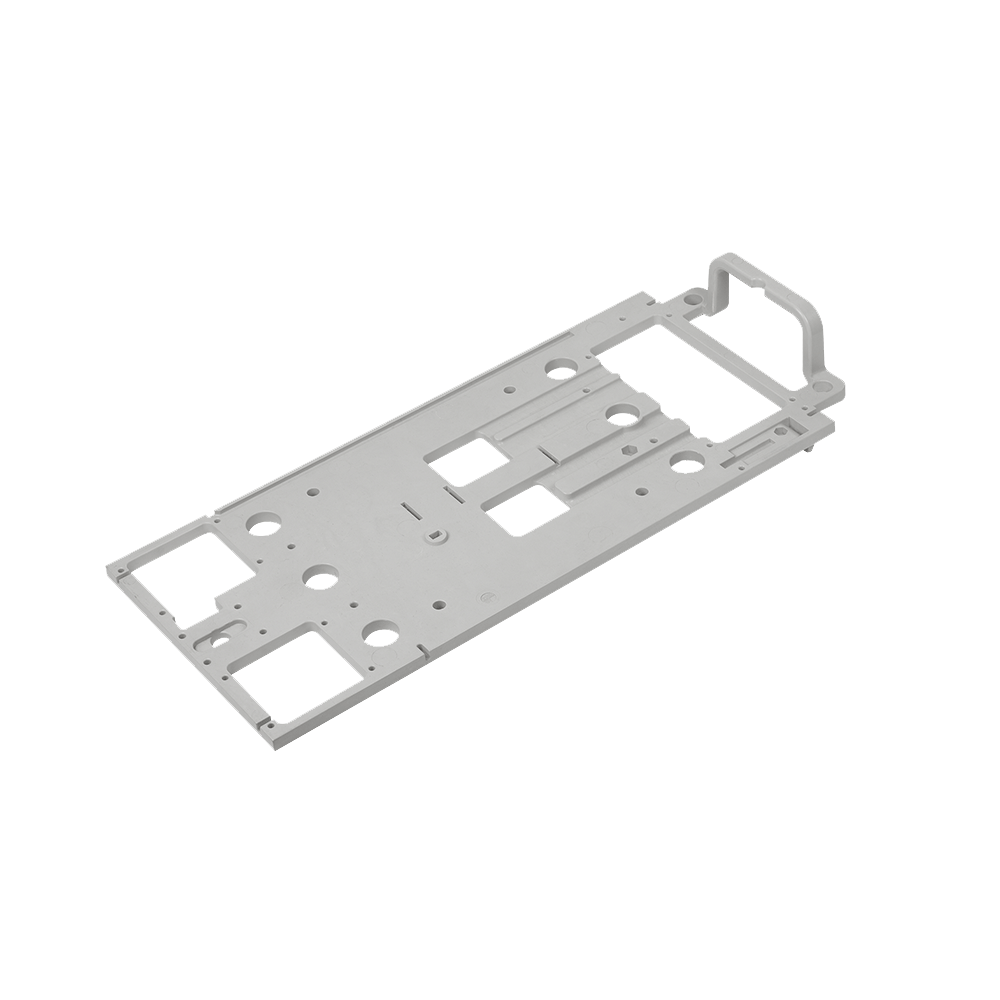

Thermoplastic

We process all commercial thermoplastics on 11 ARBURG automatic injection moulding machines:

- Polyamide (PA)

- Polycarbonate (PC)

- Thermoplastic elastomers (TPE)

- Thermoplastic polyurethanes (TPU)

- Polybutyleneterephthalate (PBT)

- Acrylonitrile butadiene styrene (ABS)

- Special high-performance plastics (PAA, PPS, PEEK)

- Polyoxymethylene (POM)

- Polyethyleneterephthalate (PET)

- Polypropylene (PP)

- Polyethylene (PE)

- Polystyrene (PS)

- Blends

… to create moulded parts of less than 1 gram to those with unit weights of approx. 1 kg. The injection force of our machinery extends up to 2200 kN.

The injection force of our machinery extends up to 2200 kN.

INJECTION MOULDING METHOD

Would you like to know how the injection moulding process works in practice? We have prepared a short video sequence which describes this in a way that is easy to understand.

Please click on the adjacent image to start the video. If you double-click, you can then switch to full-screen mode.

INJECTION MOULDING METHOD

Would you like to know how the injection moulding process works in practice? We have prepared a short video sequence which describes this in a way that is easy to understand.

Please click on the adjacent image to start the video. If you double-click, you can then switch to full-screen mode.